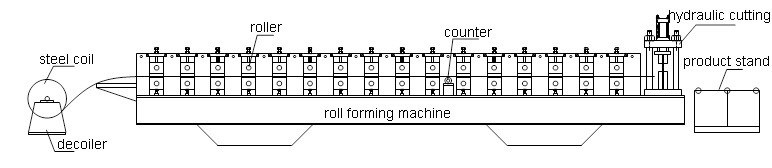

Our machine has the following advantages:

1. Adopt the guider pillar and motorized cutings.

This design make our machine stable fast cutting and long service life.

you can produce 2 different panels with 1 set of double layer roll forming machine.

2. Save cost for clients.

Current Capital is so important to run a business.

3.Save Working Space.

The workshop is not big enough to install two sets of roll forming machine for some of customers.

For this situation, double layer roll forming machine is your best choice. You only need one space of machine to produce two types of profiles.

You can check our machine over all. Not only beautiful in the surface but also good quality.

Technical parameters:

| Material Specification | colored steel sheet,galvanized steel shee |

| Thickness of coil sheet | 0.3--0.6mm |

| Forming speed | 8--15 meter/min |

| Hydraulic pressure | 58MPA |

| Index error of length | 10m±2mm |

| Hydraulic station power | 3kw |

| Main motor power | 4kw |

| Voltage | 380V3 phase 50Hz or at buyers requirement |

| Controlling system | PLC |

In order to help you know our machine much better. The following is the detailed pictures of the machine.

This design make our machine stable fast cutting and long service life.

Hydraulic cutting system:adopt the guider pillar and motorized cuttings.

Forming rollers

Specification: 45# steel, CNC Lathes, heat treated Feature: hard chrome plating, 0.05 mm

Main frame

specification: 350 H steel . feature: More stable, no shaking

Guide device

It is used to control the width and position of the steel sheet .The sheet is guided into the machine with correct position, to make sure the panel is neat and parallel.

Manual uncoiler

It is used to support the steel coil and realize the uncoiling by means of rotatory movement. The steel coil is uncoiled manually. The capacity of this uncoiler is 5 ton, and it is capable for most of the coils.

Feeding

Receiving the raw material (steel sheet), it guarantees the products are neat, parallel and everything is uniformity.

Electrical control cabinet

PLC is adopted to organize all action of the machine. The length of workpiece is adjustable according to the setting of on the PLC. Two optional control modes:Automatic and manual. By automatic mode, the machine can realize fully automatic working .

Hydraulic system

Output table

Company information

Kaiyite machinery is a leading manufacture of roll forming machine . We know well the particular requirements for the customers from different countries , and have an outstanding export team who will take your requests . Our experts and skilled workers complete the work with great precision .

We provide an extensive line of products , including roller shutter door roll forming machine ,door frame machine, roof and wall panel roll forming machine , double layer roll forming machine ,floor deck roll forming machine ,C / Z / U Purlin Roll Forming Machine , stud and track roll forming machine , ridge cap roll forming machine , downspout pipe roll forming machine , shearing machine and bending machine , slitting and cutting machine .

24 hours service the world !

Your kind inquiry or sample are warmly acceptable !

Looking forward to cooperate with your esteemed company !